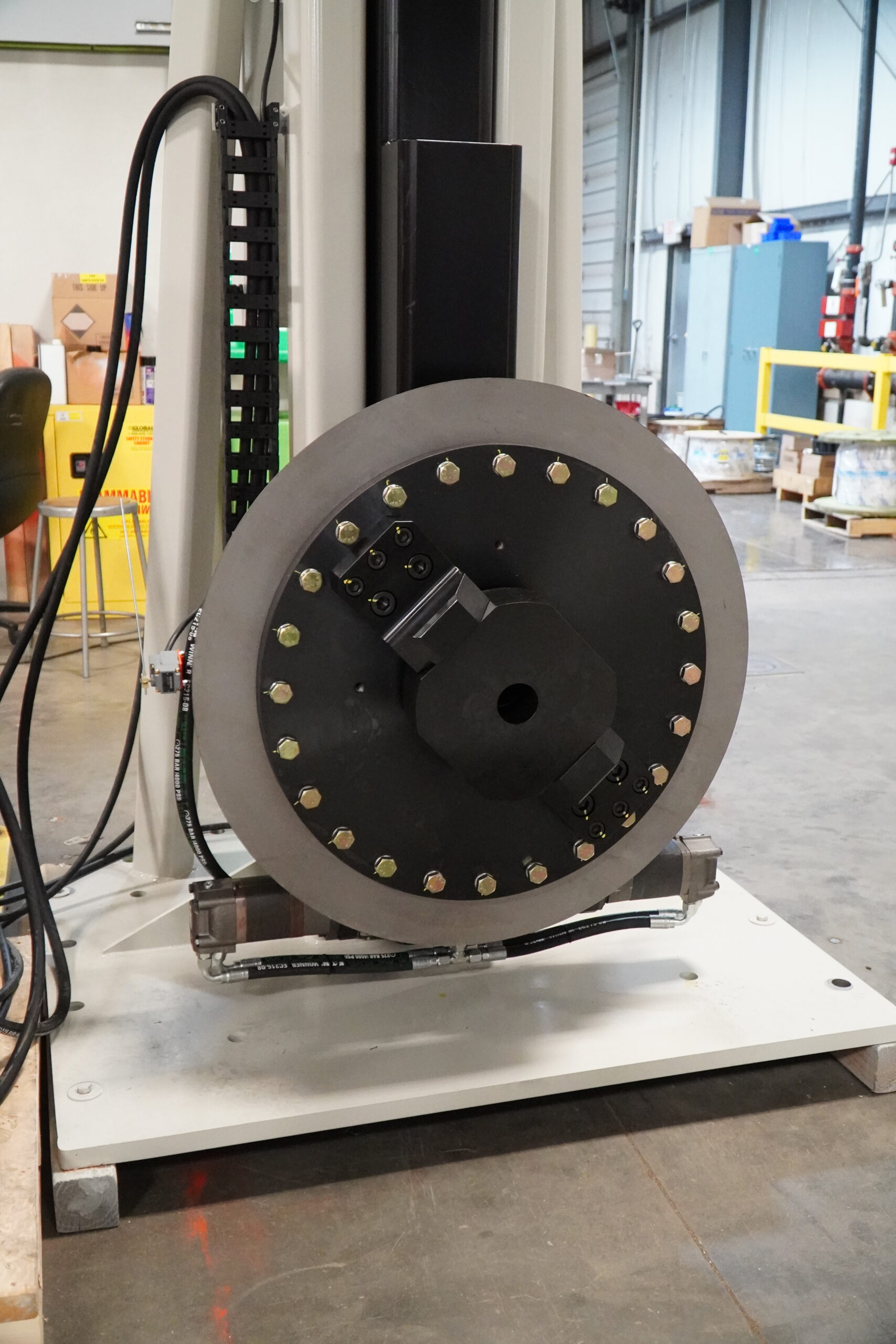

55 K Elevating Headstock & Tailstock

Elevating Fixed Headstock & Tailstock positioners are designed for elevating and tilt applications that require vertical travel and have a fixed-length part. In this application, the headstock and tailstock are bolted to the floor.

Control Platforms

Select your platform:

Programmable

ALM Positioners programmable controls offer one-touch automated positioning for maximum operator efficiency and process conformity.

SelectIntegrator

This controls package is designed for automated solutions. Our integrator model is built with the hardware you need, and nothing you don’t.

SelectFeatures: Expand All

The 4-port hydraulic/pneumatic rotary union enables infinite rotation of the hydraulic or pneumatic fixture. This is ideal for applications where there is a need for multi-turns or single direction operation.

Absolute encoder for rotation.

This feature is designed into all PNP controls and allows for seamless integration with automation equipment and robotics.

Safety shut-off button, conveniently located on each column.

Our 10-inch, easy-to-use touch screen features a simple and intuitive interface that includes error messaging, warning indicators and a diagnostic display. We’ve even built it in a way that enables people wearing a glove to operate the screen.

(This feature is not included on the Integrator user application)

The control panel is equipped with two Ethernet ports that make it possible to connect the positioner to your network. This makes it simple to upgrade to intelligent positioning software or connect to automation.

Our PNP control panes are equipped with finger-safe fuse holders and blow-fuse indicators, which make it quick and efficient to identify a blown fuse.

Our control panels are built to allow for simple integration of Insight Centerpoint™ Arc Data Monitoring Software.

Leveling is quick and efficient with our easy, one-touch auto-leveling feature. Simply push the button and your part will instantly be leveled for you.

Our powerful manual push-button hydraulic positioning gives you the ability to elevate and tilt your part.

Redundant safety features, mechanical safety stops, and hydraulic load holding check valve.

Our quick disconnect feature makes it easy to shut off power and work on cables, making you safer and more efficient.

ALM Positioners gives you the power to leverage your investment with re-deployable capital by upgrading your existing positioner and reconfiguring it into a programmable or a ready-to-integrate with an automated or robotic solution. Learn more

Eliminates the need to remove ground while positioning the part and allows infinite rotation. Options available to be installed on headstock or tailstock:

- 400 Amp allows for attachment of (1) ground cable

- 800 Amp allows for attachment of (2) ground cables

Installing scanners or light curtains is easy with ready to wire connections and pre-programmed visual indicators. Safe guard the area around your positioner with an area safety scanner. This protects the operator from the positioner, while in motion. Available options are Keyence (8.4 m) or SICK (9 m).

Safeguard the area around your positioner with an area safety scanner. This protects the operator from the positioner, while in motion. Available options are Keyence (8.4 m) or SICK (9 m).

Power your positioner with a single 480V 3PH electric drop.

With a single point shut-off system, switching your positioner off is efficient and simple.

This stand-alone hydraulic power unit (or HPU) with variable speed rotation gives you the flexibility to provide auxiliary hydraulic power for clamping and tooling needs.

Our variable speed control feature gives the operator the ability to adjust the speed at which you rotate your part.

Our wired operator pendant has 25-foot of reach, making it possible to operate your positioner from various locations around the part.

Simplify your cable management – and reduce potential cable damage – by enabling wireless communication between your headstock and tailstock. This option includes a signal strength digital readout display and features Trusted Wireless 2.0 technology for solid and reliable signal strength.

The wireless pendant empowers your welders or assembler to operate the positioner conveniently and is integrated within the safety circuit. The operator has full control of the pendant allowing them to operate the positioner from within any safe zone. The pendant comes with an integrated E-stop circuit.

(This feature is not included on the Integrator user application)

ALM Positioners-designed wobble joints make it possible to independently elevate the headstock and tailstock by +/- 8 degrees and 360 degrees tilt while out of alignment.

Options: Expand All

The 4-port hydraulic/pneumatic rotary union enables infinite rotation of the hydraulic or pneumatic fixture. This is ideal for applications where there is a need for multi-turns or single direction operation.

Absolute encoder for rotation.

This feature is designed into all PNP controls and allows for seamless integration with automation equipment and robotics.

Safety shut-off button, conveniently located on each column.

Our 10-inch, easy-to-use touch screen features a simple and intuitive interface that includes error messaging, warning indicators and a diagnostic display. We’ve even built it in a way that enables people wearing a glove to operate the screen.

(This feature is not included on the Integrator user application)

The control panel is equipped with two Ethernet ports that make it possible to connect the positioner to your network. This makes it simple to upgrade to intelligent positioning software or connect to automation.

Our PNP control panes are equipped with finger-safe fuse holders and blow-fuse indicators, which make it quick and efficient to identify a blown fuse.

Our control panels are built to allow for simple integration of Insight Centerpoint™ Arc Data Monitoring Software.

Leveling is quick and efficient with our easy, one-touch auto-leveling feature. Simply push the button and your part will instantly be leveled for you.

Our powerful manual push-button hydraulic positioning gives you the ability to elevate and tilt your part.

Redundant safety features, mechanical safety stops, and hydraulic load holding check valve.

Our quick disconnect feature makes it easy to shut off power and work on cables, making you safer and more efficient.

ALM Positioners gives you the power to leverage your investment with re-deployable capital by upgrading your existing positioner and reconfiguring it into a programmable or a ready-to-integrate with an automated or robotic solution. Learn more

Eliminates the need to remove ground while positioning the part and allows infinite rotation. Options available to be installed on headstock or tailstock:

- 400 Amp allows for attachment of (1) ground cable

- 800 Amp allows for attachment of (2) ground cables

Installing scanners or light curtains is easy with ready to wire connections and pre-programmed visual indicators. Safe guard the area around your positioner with an area safety scanner. This protects the operator from the positioner, while in motion. Available options are Keyence (8.4 m) or SICK (9 m).

Safeguard the area around your positioner with an area safety scanner. This protects the operator from the positioner, while in motion. Available options are Keyence (8.4 m) or SICK (9 m).

Power your positioner with a single 480V 3PH electric drop.

With a single point shut-off system, switching your positioner off is efficient and simple.

This stand-alone hydraulic power unit (or HPU) with variable speed rotation gives you the flexibility to provide auxiliary hydraulic power for clamping and tooling needs.

Our variable speed control feature gives the operator the ability to adjust the speed at which you rotate your part.

Our wired operator pendant has 25-foot of reach, making it possible to operate your positioner from various locations around the part.

Simplify your cable management – and reduce potential cable damage – by enabling wireless communication between your headstock and tailstock. This option includes a signal strength digital readout display and features Trusted Wireless 2.0 technology for solid and reliable signal strength.

The wireless pendant empowers your welders or assembler to operate the positioner conveniently and is integrated within the safety circuit. The operator has full control of the pendant allowing them to operate the positioner from within any safe zone. The pendant comes with an integrated E-stop circuit.

(This feature is not included on the Integrator user application)

ALM Positioners-designed wobble joints make it possible to independently elevate the headstock and tailstock by +/- 8 degrees and 360 degrees tilt while out of alignment.

Quality Policy

ALM Positioners strives to provide customer satisfaction by delivering quality products on time, providing outstanding customer service, and supporting a company culture of continuous improvement.